OSG USA, INC. has introduced its highly anticipated Tooling Solutions Product Catalog in print and in digital versions. The latest catalog edition is over 1,700 pages and includes over sixty new list numbers of its latest and greatest cutting-tool additions.

OSG Tooling Solutions Product Catalog Features:

- 60+ NEW List Numbers

- Refreshed Design

- Improved PDF Usability – Bookmarks, In-Document Shortcuts, Item Links to Website

- New QR Codes to Easily Access Product Series Details and Product Videos

- New Stock Status Columns to Help Easily Identify Product Availability

The OSG Tooling Solutions Product Catalog can be accessed digitally here. Customers may also request a free hard copy by contacting OSG Customer Service at 1-800-837-2223 or may order it online here.

_1000.png)

We are pleased to announce the expansion of our HY-PRO® CARB VGM offering with the addition of the NEW VGM-NIK high-performance variable geometry nicked end mills.

The following list numbers are associated with the HY-PRO® CARB VGM Series Expansion:

- NEW! List #VGM5-NIK HY-PRO® CARB VGM5-NIK

- NEW! List #VGM7-NIK HY-PRO® CARB VGM7-NIK

The HY-PRO® CARB VGM-NIK offers the following features & benefits:

✓ Variable Index - Reduces vibration during machining

✓ Unique Flute Geometry - Maintains excellent cutting-edge sharpness and tool rigidity

✓ EXO Coating – Provides longer tool life through exceptional wear and heat resistance.

✓ Chipbreaker – Creates small manageable chips

_1000.png)

We are pleased to announce the expansion of our HY-PRO® CARB VGM offering with the addition of the NEW VGM3-AL high-performance variable geometry end mills.

The following list numbers are associated with the HY-PRO® CARB VGM Series Expansion:

- NEW! List #VGM3-AL HY-PRO® CARB VGM3-AL

The HY-PRO® CARB VGM3-AL offers the following features & benefits:

✓ Variable Index - Reduces vibration during machining

✓ Unique Flute Geometry - Maintains excellent cutting-edge sharpness and tool rigidity

✓ Center Cutting – 3 cutting edges to center; ideal for plunging and ramping

Stable and high efficiency in small diameter deep-hole applications.

- Hiroyuki Amano, OSG Corporation Applications Engineer (Drill Development Division)

OSG Corporation has recently released the ADO-MICRO – the company’s first small diameter carbide drill with oil holes designed for stable and high efficiency drilling in deep-hole applications. The sense of size upon hearing the phrase “small diameter” will be understood differently among users in the manufacturing industry.

The ADO-MICRO has a lineup of drill diameters from 0.7 mm up to 2 mm for drill lengths of 2xD and 5xD, and diameter 1 mm to 2 mm for drill lengths of 12xD, 20xD and 30xD. The product name ADO-MICRO may seem to be associated with the unit prefix micro (µ), but it was named to simply imply smallness in size regardless of the unit.

For small diameter drilling, options such as carbide drills and HSS drills using external coolant are available. However, today’s machining needs require greater stability, higher efficiency and longer life than ever before. There is no exception in small diameter deep-hole applications, with growing needs for coolant-through small diameter drills.

Tool Geometry

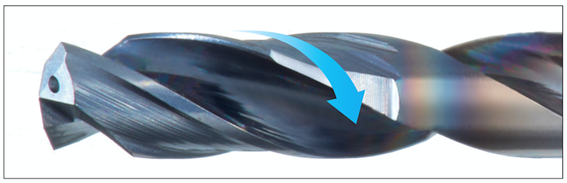

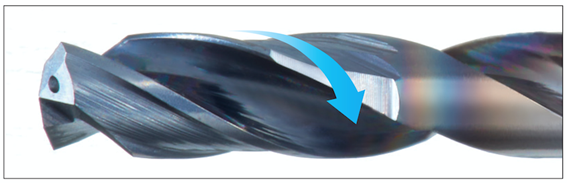

One of the keys for successful small diameter drilling is trouble-free chip evacuation. As illustrated in figure 1, chips generated at the tip of the tool flow in the direction of the blue arrow. However, if there is insufficient space in the flute, cutting chips cannot evacuate smoothly, which causes the drilling accuracy to deteriorate and increases the probability of tool breakage. Therefore, by providing a wider flute specification at the area where the tip of the blue arrow locates, as depicted in figure 1, cutting chips are able to be discharged without difficulty, leading to stable machining.

Figure 1. Extended flute

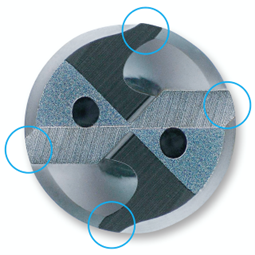

In addition, the ADO-MICRO employs a unique double margin geometry (as depicted in figure 2) in all sizes to enable stable machining even in deep-hole applications. In order to ensure the rigidity of the cutting edge, the margin is set to the minimum necessary length. However, micro sludges can be easily accumulated around the outer periphery of the cutting tool, which is a key cause of abrupt tool breakage. To resolve this challenge and to achieve an overall balance, an extended flute configuration is incorporated to provide sufficient exit room as shown in figure 3.

Figure 2. Four support points with the double margin design

Figure 3. Exit room at end of margin

Oil Holes

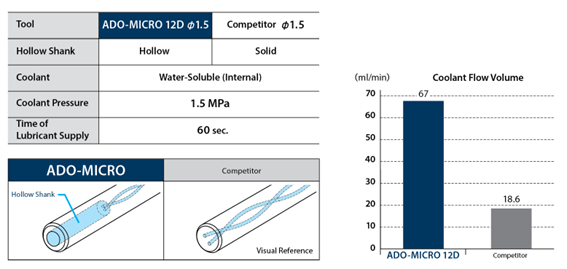

The ADO-MICRO features a straight hollow shank design where coolant is injected in addition to the two spiral oil hole paths. This configuration increases coolant discharge from the tool tip. Without the hollow shank configuration, greater pressure is required in order for the coolant to pass through the thin oil hole paths. With the hollow shank feature, pressure loss is reduced, which increases the coolant flow volume. As illustrated in figure 4, with a higher coolant flow rate, cutting chips can be more effectively evacuated, thereby enabling stable machining.

Figure 4. Relationship between shank structure and coolant flow volume

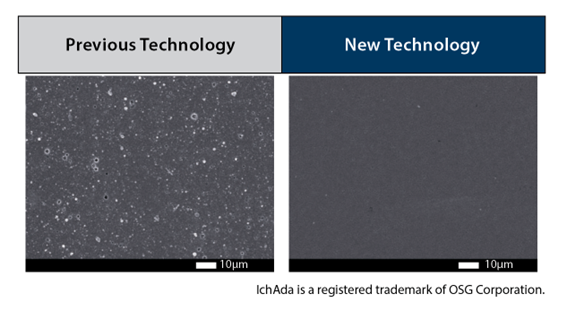

OSG’s Latest Coating Technology: IchAda Coating

Another key element for achieving stable processing in small diameter deep-hole application is coating technology. The role of tool coating is to provide wear resistance and heat resistance to prolong tool life, which is particularly important to small diameter tooling. As illustrated in figure 5, the coating surface by conventional technology is not smooth, which may interfere with the performance of chip evacuation. OSG’s latest IchAda coating, on the other hand, provides excellent surface smoothness in conjunction with high wear resistance and heat resistance to enable small diameter tools to achieve long tool life by improving adhesion.

Figure 5. Surface of coating

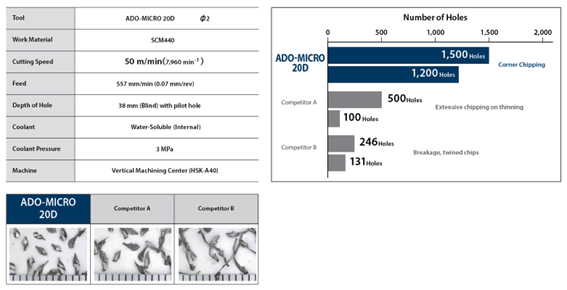

Cutting Data

Figure 6 demonstrates a comparison of tool life between the ADO-MICRO and two other tooling manufacturers’ products in the machining of SCM440. The competitor drills have chipped or have broken at the initial machining stage. The ADO-MICRO, on the other hand, was able to achieve long tool life stably due to its superior chip evacuation capability by breaking chips into small and manageable pieces.

Figure 6. Stable and long tool life in SCM440

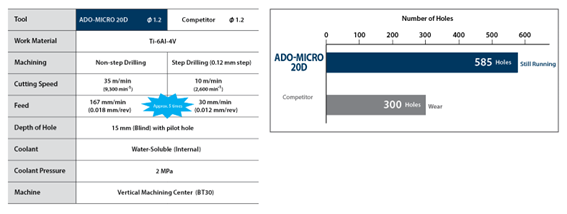

The ADO-MICRO demonstrates stable performance even in difficult-to-machine titanium alloy applications. As shown in figure 7, the competitor drill struggled with chip evacuation, thus requiring step processing. However, with the ADO-MICRO, step processing can be eliminated while achieving approximately five times the drilling efficiency. The ADO-MICRO was still in good shape after doubling the competitor drill’s tool life, allowing it to be used on other applications.

Figure 7. Efficiency improvement in titanium alloy

The ADO-MICRO’s unique tool geometry and OSG’s original IchAda coating allow non-step drilling even for deep-hole applications, enabling high processing efficiency. By eliminating common complication in small diameter deep-hole drilling, the ADO-MICRO is able to excel with stable performance in a wide range of work materials including stainless steel. In addition to standard stock items, OSG also offers customization services with tailored solutions for each and every manufacturer’s specific machining needs.

For more information: Click Here

(1)_1000.png)

We are pleased to announce the expansion of our PHOENIX® PDZ offering with the addition of the NEW PDZ-3D indexable flat drill.

The following list numbers are associated with the OSG PHOENIX® PDZ Series Expansion:

- NEW! List #52514 OSG PHOENIX® PDZ-3D (inch)

- NEW! List #78538 OSG PHOENIX® PDZ-3D (metric)

The PHOENIX® PDZ indexable flat drill offers the following features & benefits:

✓ Flat bottom cutting-edge configuration is compatible with a wide range of applications - drilling, counterboring, inclined surfaces

✓ Enhanced muscle breaker allows for superior chip breaking capability during drilling, counterboring and turning

✓ High precision finishing on flutes improves rigidity, efficient chip evacuation and reduces cutting force

✓ Available in Inch and Metric sizes

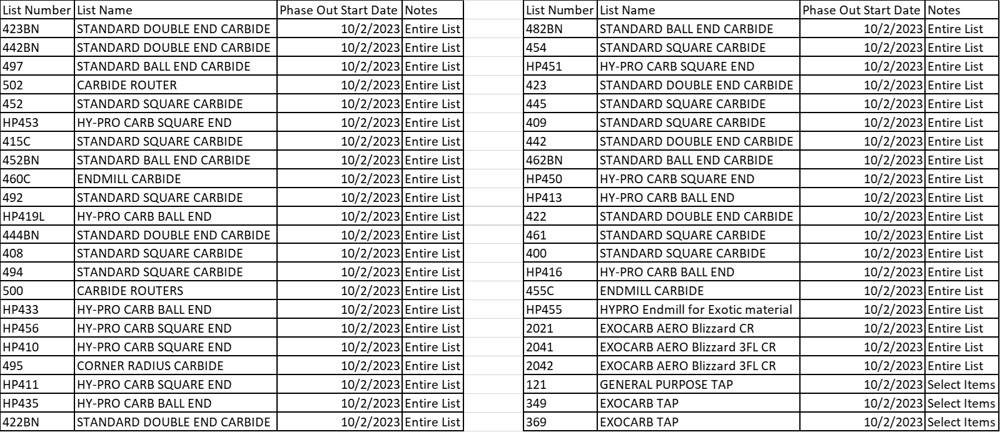

We are announcing the phase out and discontinuation of the following list numbers:

Limited quantities of the above products continue to be available, while supplies last.

_1000.png)

We are pleased to announce the expansion of our HY-PRO® CARB VGM end mill series with the addition of the NEW VGM3-AL! The HY-PRO® CARB VGM3-AL is a is a series of Variable Geometry end mills for High Speed Machining in Aluminum and Non-Ferrous Materials.

The following list numbers are associated with the NEW VGM3-AL series:

- NEW! List #VGM3-AL

The HY-PRO® CARB VGM3-AL end mill offers the following features & benefits:

• Center Cutting - 3 cutting edges to center; ideal for plunging and ramping.

• Variable Index - Reduces vibration during machining.

• Unique Flute Geometry - Maintains excellent cutting edge sharpness and tool rigidity

OSG USA, Inc. promotes Andrew Matt to Vice President of Human Resources

St. Charles, IL- September 1, 2023

Andrew Matt, the former Director of Human Resources, will be responsible for leading the development and execution of Human Resources strategies for OSG USA, Inc.

“I am very excited to support OSG USA, Inc. in my new role by continuing to evolve the role of human resources within the organization. I’m committed to ensuring that HR becomes the collaborative partner to support our journey of innovation and excellence.”

Andrew started his career at OSG in 2020 as Regional Human Resources Manager, and prior to his career with OSG, Matt was an Executive Director of Human Resources and Organizational Development with BathWraps (RHT, Inc.) and originally began his Human Resources career with United Stationers (Essendant) as their Manager of Performance Improvement and Training in 2000.

Andrew earned his Masters in Business Administration from Marquette University in 1994 after earning Bachelor of Science degree in Organizational Management and Marketing from Marquette University. Andrew is a Senior Certified Professional (SHRM-SCP) since 2020. He is a longtime Chicago area native growing up in Riverside and residing in Westmont with his wife and three children.

OSG wouldn’t be one of the best places to work without our innovators and leaders that come to work each day and live by our P.R.I.D.E. values!

2022 Innovator of the Year Recipients:

Corporate Support/Services:

Bensenville Factory 1st shift:

Bensenville Factory 2nd shift:

Operations:

OSG Parma Factory:

2022 Elite Leader of the Year Recipients:

Corporate/Operations:

Bensenville Factory:

OSG Parma Factory:

Sales:

Contact Us

Contact Us  Product Search

Product Search