Pictured from left to right: Ted Pierce, Shop Foreman/CNC Programmer; Charlie Wright, Jr., General Manager; and John Hargrove, Lead CNC Setup/Operator

The U.S automotive industry has experienced rapid growth for the last several years. In 2015, US auto sales hit a record high. According to DeBord, cheap gas and easy credit as well as the low unemployment rate contributed to the booming auto sales. The demand for reliable and high-tech cars has increased.

In order to keep up with this increasing demand, U.S. auto manufactures have been strict about meeting customers' time constraints. Efficiency and productivity has become essential more than ever for both of the auto and the auto parts manufacturers.

Micro Technology is an auto parts manufacturer located in Tullahoma, TN. After years of experience as a machinist, the owner, Charlie Wright Sr. started the company in 1987 with just 3 mills, 3 lathes, 1 radial arm drill and 1 brand saw. After 30 years, his son, Charlie Wright Jr. is in the process of taking over the company.

The company mainly produces parts that are used to mount to automotive engine blocks to be robotically transported through assembly lines. They produce various models and quantities annually and these parts are 2-part sets which are machined and then assembled requiring additional time before shipping out to the customers. While the soon to be new owner, Wright Jr., focuses on quality and accuracy of his products, he also strives for improved efficiency and productivity. He was looking for ways to cut machining time to meet strict time constrains of his customers, so he reached out to DGI and OSG's district manager, Philip Woody.

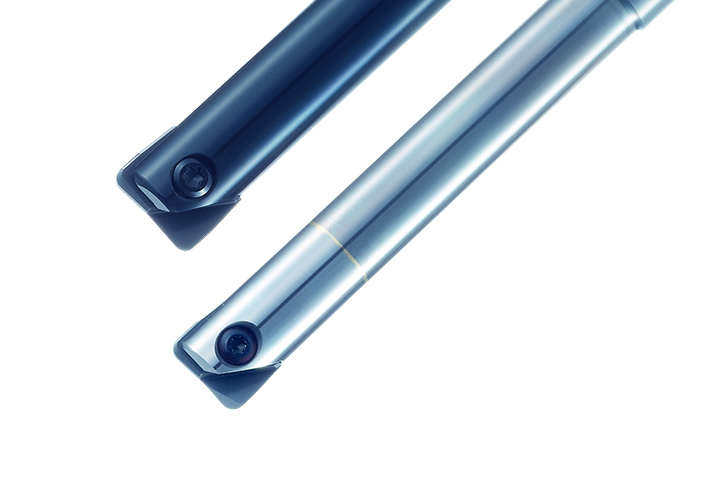

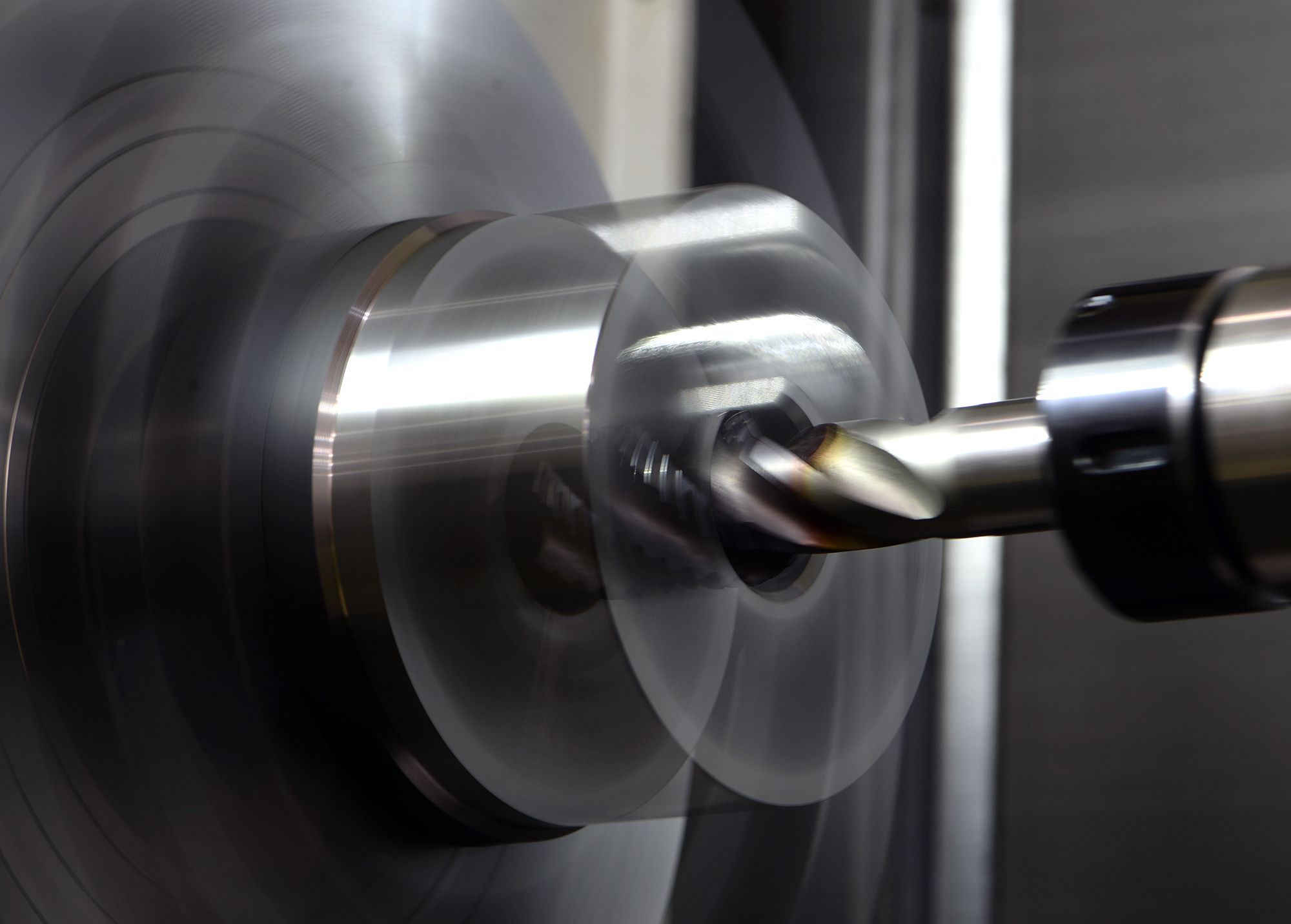

The company uses HAAS VF-3 with CAT40 taper tools. The part being machined is 6061 Aluminum and the tolerance requirement is +/- 0.002" to achieve the precise geometry and finish the company needs. Wright Jr. used to machine the parts with a competitor's face mill which ran at 3,000RPM 120IPM with 1.25" axial and 1.2" radial depth of cut. He wanted to improve productivity without sacrificing quality and accuracy.

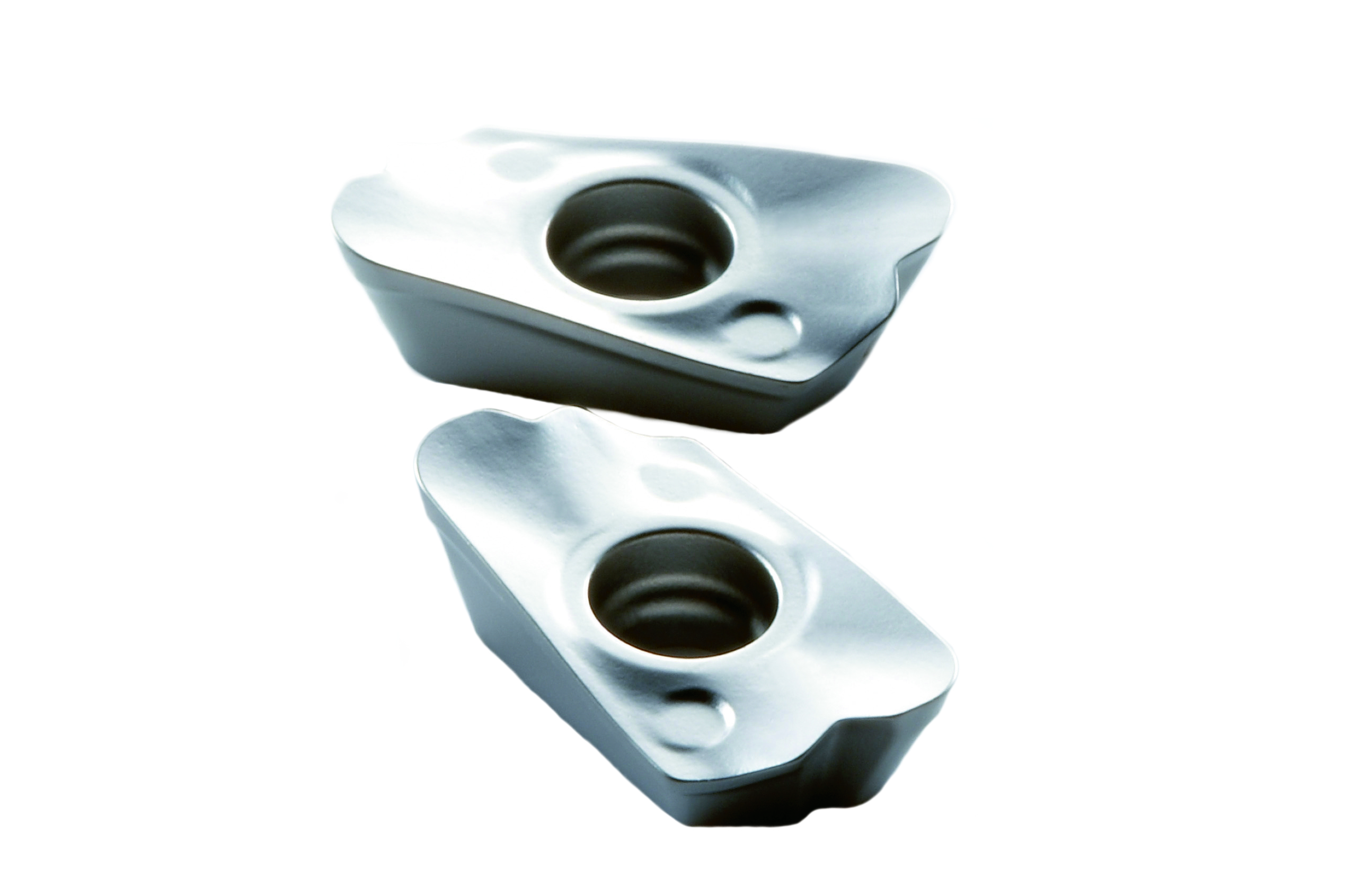

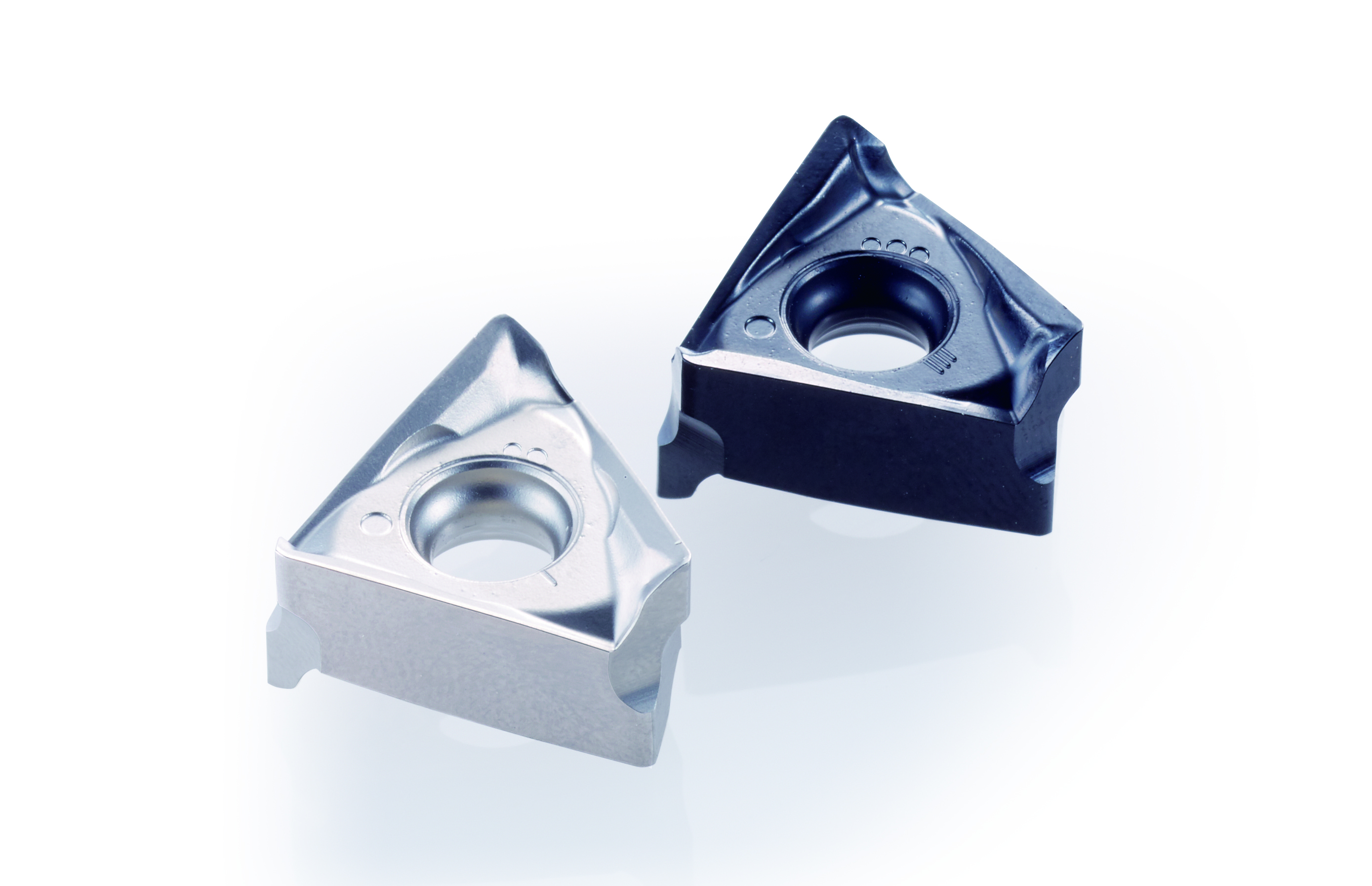

Woody recommended OSG's PHOENIX® PRC indexable radius cutter (EDP #7800404) with 12mm diameter aluminum grade insert (EDP# 7811013.) The PRC ran at 5,780RPM 345IPM surpassing speeds and feeds of the competitor tool. The company was able to cut the machining time by roughly 25 minutes per part achieving a 50 minute reduction per set! In addition to the machining time, the company was able to improve the surface finish with OSG's PRC.

"This tool [the PRC] was extremely instrumental in achieving our required tolerances and meeting delivery deadlines of my customers," said Wright Jr.

Wright Jr. is excited for his new journey as an owner with the reliable tools from OSG and Woody is walking alongside with him to support his needs and to reach even greater heights.

Source:

DeBord, Matthew. (2016, December 21st). The US auto industry may surprise everyone in 2017. Business Insider. Retrieved from http://www.businessinsider.com/us-auto-industry-growth-in-2017-2016-12

(1)_1000.png)

Contact Us

Contact Us  Product Search

Product Search