The perfect combination of cutting tool, tool holder, and machine tool takes mold manufacturer to a new level of productivity

Steve Lauman | District Manager

For the past 20 years, Lifetime Products Incorporated’s mold shop has been producing aluminum blow molds to support the company’s production of plastic tables, chairs, coolers, kayaks, outdoor sheds, and much more. Lifetime first started its legacy in the sporting goods industry in 1986, introducing a breakthrough basketball system that can be adjusted in seconds. It was the first system that allows basketball hoop homeowners to easily raise and lower the height quickly. Since then, Lifetime has become the world’s largest manufacturer of residential basketball hoops as well as folding tables and chairs, selling products in 58 countries around the globe. Today, the company has grown from 15 employees in a partial warehouse to over 1,500 employees around the world, serving the sporting goods, folding furniture, lawns and garden, playground and the watersports markets.

For the past 20 years, Lifetime Products Incorporated’s mold shop has been producing aluminum blow molds to support the company’s production of plastic tables, chairs, coolers, kayaks, outdoor sheds, and much more.

Lifetime’s global business and manufacturing headquarters is located in Clearfield, Utah, USA. Lifetime’s mold division, which was established in 1999, currently employs 23 staff and has an estimate production area of 16,000-square-feet. As an organization that is committed to innovation and quality, Lifetime is constantly looking for ways to improve their manufacturing process.

For some time, Lifetime has been searching for new solutions to enhance efficiency in their mold production primarily made of aluminum materials such as 6061, 7075 and QC10. In terms of production volume, Lifetime on average produces 20 to 30 molds per year. Lifetime Mold Engineer Dennis Norman and Lifetime Head CNC Programmer Randy Macari are well versed on high speed machining and how it can help them attain much higher productivity. They also understood the required three essential components in order to maximize the benefit of high speed machining – high performance tooling capable of running high speed machining programs, precision holders to secure tool engagement at high rpms, and a machine tool with features such as look ahead software and the ability to run at high speeds.

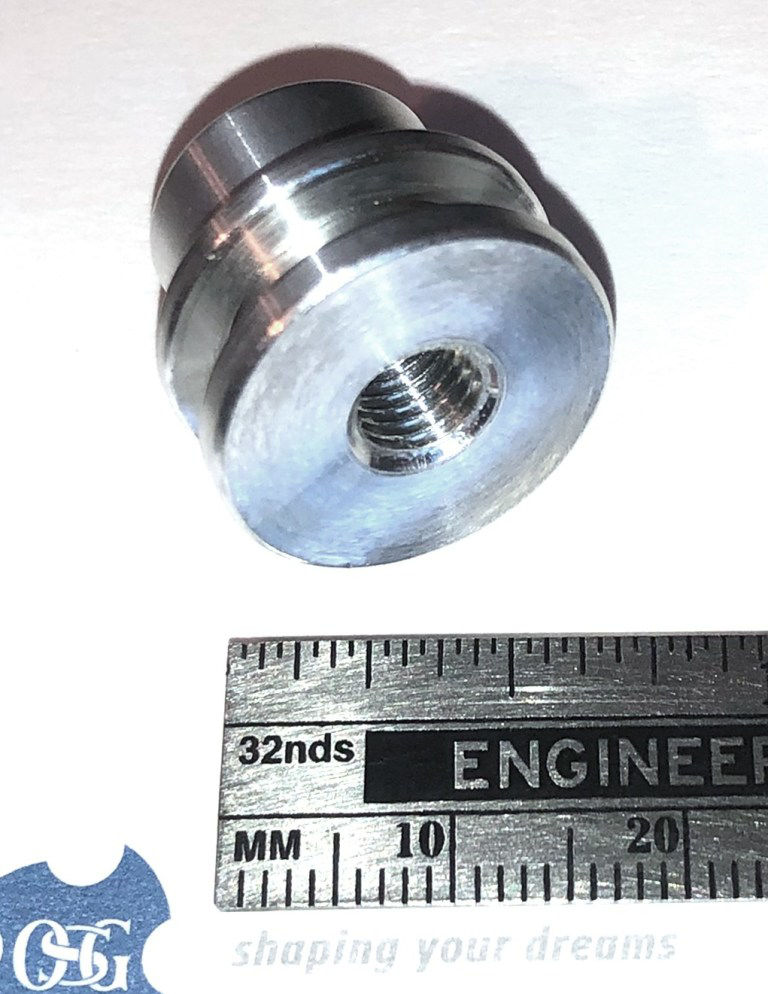

Lifetime’s mold production is primarily made of aluminum materials such as 6061, 7075 and QC10.

The first requirement of high-performance tooling was met when Lifetime began utilizing OSG end mills. Lifetime’s previous tooling choice was a 3/8” 3-flute end mill that was used at 6,000 rpm and 60 ipm. The second requirement was met with OSG’s HY-PRO shrink fit holder and shrink fit technology. OSG’s balanced holder gave Lifetime the ability to mill in excess of 20,000 rpm. The fulfillment of the first two requirements has greatly improved tool life and performance at Lifetime. However, further progress was held back because Lifetime’s older machine tools are incapable of running high speed machining programs. It all changed when this past year, a new Mazak FJV-60/120 vertical mill arrived with look ahead controls designed for high speed machining along with a high-pressure coolant through spindle. With the equipment update, Lifetime is now able to fully leverage OSG’s Exocarb Aero Blizzard high performance carbide end mill.

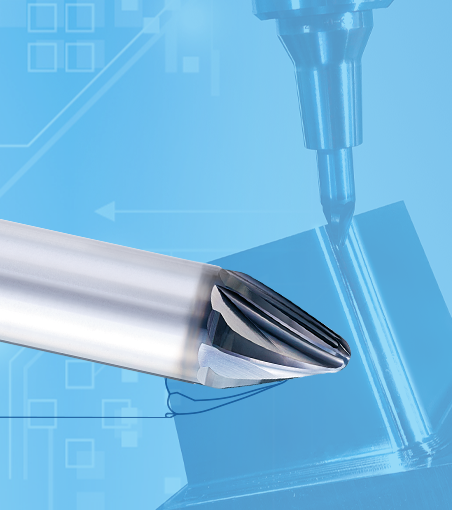

The Exocarb Aero Blizzard series is a part of the OSG premium line of carbide high performance end mills specifically designed for aluminum and copper alloys. The series’ special end cut gashing and offset teeth permit large depths of cut and maximum feed per tooth. Made with polished flutes to enhance tool life and reduce built up edges, the Blizzard end mill series is engineered to yield high metal removal rates in roughing applications while providing a superior finishing.

The Exocarb Aero Blizzard series is a part of the OSG premium line of carbide high performance end mills specifically designed for aluminum and copper alloys. The Exocarb Aero Blizzard end mill series is available in various end styles, such as square, corner radius and ball.

Combined with the new Mazak vertical machining center, OSG’s 3/8” 3-flute Blizzard end mill is now able to reach its full potential, with parameters as high as 15,000 rpm and 220 ipm to generate unparalleled results in productivity. These improvements across all the different milling operations at Lifetime have created an average of 25 percent cycle time reduction. A typical mold is now machined and built in less than 12 weeks, down from an average of 16 weeks. In addition to increased speeds and metal removal rates, Lifetime also saw much improved surface finish, which lowered labor costs by reducing the amount of labor time needed to polish the cavity components of each mold. The combination of a quality tool with precision tool holder engages the workpiece in a more rigid and stable environment, thus resulting in a better surface finish. The overall polishing time was reduced by more than 75 percent. Mold polishing in general added 40 hours to the mold build time, which has now been reduced to eight hours.

Combined with Lifetime’s new Mazak vertical machining center, OSG’s 3/8” 3-flute Blizzard end mill is able to reach its full potential, with parameters as high as 15,000 rpm and 220 ipm to generate unparalleled results in productivity.

“OSG’s Blizzard end mill’s performance helped exceed our objectives needed to deliver our molds faster and better,” said Lifetime Products CNC Programmer Randy Macari.

From left, Lifetime CNC Programmer Randy Macari and OSG USA District Manager Steve Lauman pose for a photograph at Lifetime’s manufacturing facility in Clearfield, Utah, USA.

High productivity can only be achieved with the perfect combination of cutting tool, tool holder and machine tool. By constantly improving, innovating and leveraging the latest manufacturing technologies, Lifetime will continue its journey in creating affordable and lasting products for consumers and their families.

For more information on OSG’s Exocarb Aero Blizzard series and Lifetime Products Inc.

.jpeg)

Contact Us

Contact Us  Product Search

Product Search