Jacob Van Oost, District Manager

The die and mold industry is a very competitive sector.

Shops are constantly ?striving to? outperform? competitors by ?quoting

shorter ?delivery time, better finish, and lower cost per? unit. At OSG, we go

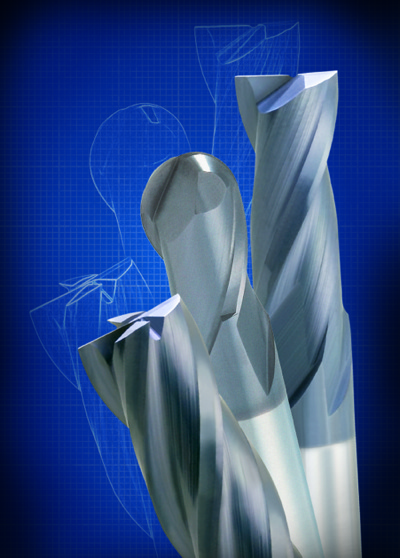

beyond the quote to demonstrate our abilities in action. With our EXOCARB®

WXS® High Feed Corner Radius End Mill, shops are able to

achieve faster feed rates, superior surface finishes, and better overall cycle

times.

Working with a shop specializing in automotive work in Muskegon, MI, the engineer there wanted a tool that could speed up a process for adding a groove in a P-20 with a 0.25” wide gasket track going around the whole part. The customer originally had it programmed with a 0.25” end mill, but it was taking 3.25 hours to put in the groove. After evaluating the application, we recommended OSG’s EXOCARB® WXS® High Feed Corner Radius End Mill to get the job done.

This corner radius cutter is extremely rigid with a long reach capability. The reverse taper on the cutting edge prevents chattering and eliminates dwell marks on sidewalls. With a new WXS® coating, this end mill oxidizes at around 1300° C, allowing it to withstand much greater heat than competitor tools that are treated with TiAlN.

Initially, we wanted to start the tool at 1,300 RPM and 715 IPM. However, after getting a more detailed look into the program, we realized that the machine for this job could not handle such an aggressive feed rate. To resolve this issue, we decided to cut everything in half, bringing it down to 650 RPM and 357 IPM. Using the EXOCARB® WXS® High Feed Corner Radius End Mill with a light depth of cut, this part of job was completed two hours faster than the original method, and the program time was reduced to merely 35 minutes. The customer was thrilled with the result, and they now use this corner radius end mill to reduce production time overall.

Beyond the automotive industry, this dynamic tool can be applied? to many applications in die/mold shops. For detailed, 3D contoured parts, it can be used in conjunction with the true 4-flute ball mill. It leaves smaller scallops and has faster metal removal rates than that of ball nosed end mills, making it ideal for roughing. Smaller scallops also makes finishing with the true 4-flute easier and faster, allowing customers to go from roughing straight to finishing, bypassing semi-roughing altogether.

To stay ahead of the competition with faster production, OSG’s EXOCARB® WXS® High Feed Corner Radius End Mill will bypass extra processes along the way.

Contact Us

Contact Us  Product Search

Product Search